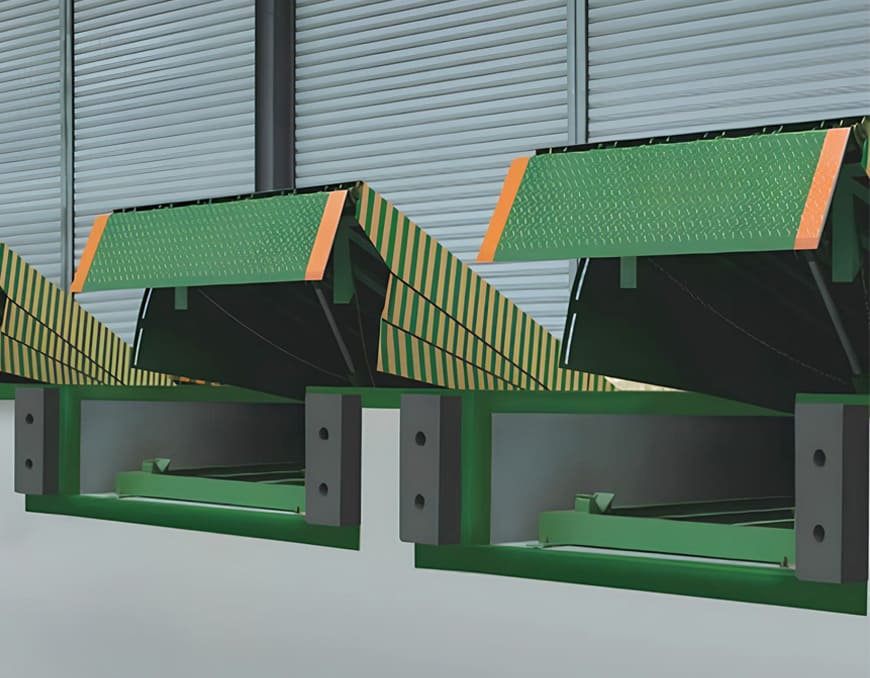

Dock Leveller Models

Scissor Lift With Galvanised

Scissor Lift With Stainless Steel

Scissor Lift With Explosion Proof

Scissor Lift With Tilt Platform

Scissor Lift With Turnable

Scissor Lift With Turnable

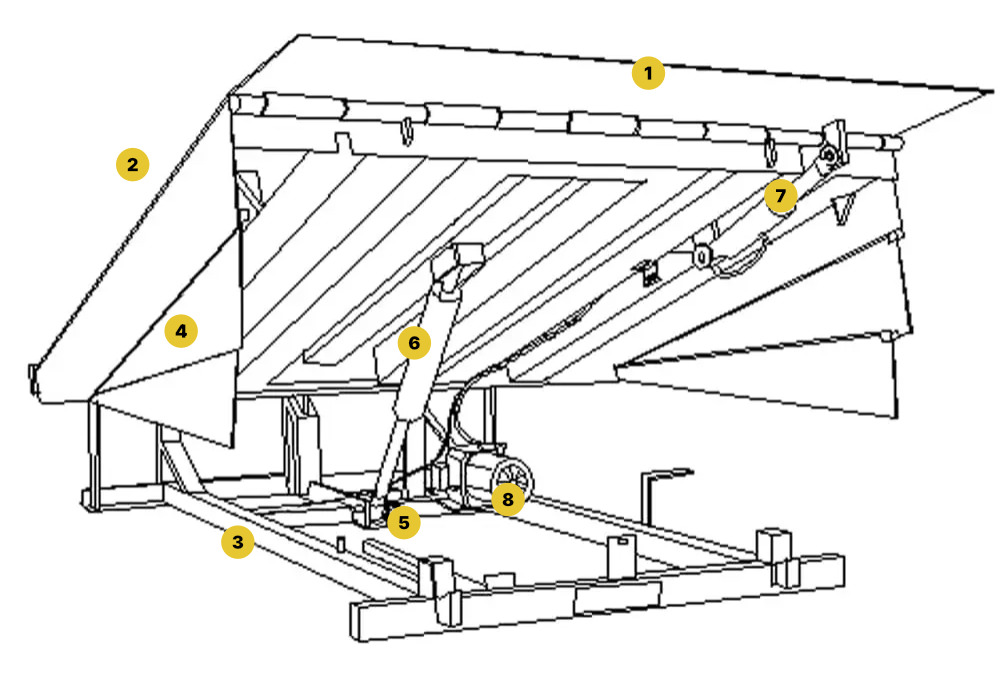

Major Components for Dock Leveler

- Tongue Plate

The tongue plate of a dock leveller plays a vital role as the connecting link between trucks and the dock during cargo loading and unloading. When a truck is stationed at the loading dock, the tongue plate extends from the dock leveller to establish a secure connection with the truck bed. This stable link facilitates the seamless movement of forklifts or other material handling equipment between the dock and the truck. - Panel

The dock panel of a dock leveller functions as an anti-skid plate, offering a stable and slip-resistant surface for loading and unloading activities. Its design and specifications are tailored according to the load capacity needs of the dock leveller. The underlying structure of the dock panel is meticulously engineered to withstand the specified load capacity. These structural elements are designed to deliver ample strength and support, ensuring secure and dependable performance during cargo transfers - Bottom Frame

Our dock levellers are equipped with a sturdy bottom frame crafted from meticulously chosen rectangular steel tubes. The frame’s size is tailored to the load capacity and platform dimensions, ensuring outstanding support and stability. Emphasising structural integrity and longevity, we employ thicker and more robust steel tubes for higher load capacities. With our top-quality dock levellers, you can rely on consistent performance and enduring durability. Get in touch with us today to explore our selection of dock levellers and find the perfect solution for your business needs. - Skirt Plate

The skirt plates are firmly affixed to the sides of the dock leveller, extending downwards to shield the exposed space beneath the platform. Serving as both a visual cue and a physical barrier, they effectively remind and prevent individuals from straying into unsafe zones while the dock leveller is in operation.

- Support Foot

The support foot is engineered to offer extra stability and support, particularly during maintenance operations. When maintenance or servicing is necessary, the support foot is deployed to establish a stable foundation for the dock leveller. It serves as a safety measure, preventing unintended shifts or instability while personnel are engaged in work on or around the equipment. - Large Plate Oil Cylinder

We prioritise efficiency and reliability in our dock levellers. The Large Plate Oil Cylinder is meticulously chosen and engineered to effortlessly manage the expected load capacity. Selecting the right size of the oil cylinder ensures optimal performance and safety during the lifting operation. - Tongue Oil Cylinder

The Tongue Oil Cylinder is responsible for raising and lowering the tongue plate of the dock leveller, ensuring it aligns accurately with the truck’s position. - Pumping Style

The pumping station of our dock leveller is engineered with a power capacity matching the load capacity, ensuring peak performance and efficiency during operation. Furthermore, our pumping station is furnished with a motor featuring an emergency decline feature. In case of a power outage, this feature enables a controlled lowering of the dock leveller, ensuring secure and dependable operation even without a power source.

Deck Leveller Surface Treatment

Dock Leveller With Galvanised

Enhanced outdoor rust resistance capabilities.

Colour Optional

The colour of dock levellers can be customised according to surroundings

Not found what you are looking for?

We could still help! Contact our team to find out more.